Sourcing is a process in which the firm makes an attempt to find out the best vendor for supplying materials with standard quality and the right price. Also, it ascertains the scope of strong and lasting relationships with vendors. Further, it maintains the relationship over a period of time for mutual benefit.

Sourcing is a process in which the firm makes an attempt to find out the best vendor for supplying materials with standard quality and the right price. Also, it ascertains the scope of strong and lasting relationships with vendors. Further, it maintains the relationship over a period of time for mutual benefit.

In contrast, procurement is the process of buying the materials in the right quantity and quality, which the firm requires to carry out the production process.

Do you guys know that raw material forms 60 to 70% of the cost of the product? Thus, the firm should give preference to purchasing. It is important because acquiring materials is the next objective step post-planning process.

In this post, we will explore the differences between sourcing and procurement in detail.

Content: Sourcing Vs Procurement

Comparison Chart

| Basis for Comparison | Sourcing | Procurement |

|---|---|---|

| Meaning | The sourcing process means ensuring that the company possesses suitable sources for the goods and services it requires. | Procurement is the process of acquiring products and services from vendors via direct purchasing, competitive bidding or tendering. |

| Related to | 'Who' is going to provide the supplies? | 'What' kind of supplies the firm requires? |

| Focuses on | Finding out and assessing supplier. | The whole process, right from need identification to final payment |

| Supply Chain | It is related to building and managing the supply chain and also creating a list of vendor options for resilience. | It leverages supply chains to make certain a constant flow of inputs and supplies to the organization. |

| Involves | Identifying the suppliers to fulfil business needs | Making certain that the business gets what it requires. |

| Assist in | Streamlining the procurement of materials. | Ensuring that there is a smooth flow of raw materials to make sure that there is no disruption. |

What is Sourcing?

Sourcing involves looking for suppliers, assessing and contracting them and maintaining a chain of vendors to cater for the needs of the organization. For this, the company must determine what kind of raw materials and in what quantity they require in future. It involves

- Setting up rules for partnerships

- Creating and maintaining a list of approved vendors

- On-boarding and offboarding procedures

- Tracking of vendor performance etc.

Decisions relating to sourcing consider:

- Factors influencing buying decisions

- Factors deciding where to buy

- Buying centres

- Buying situations

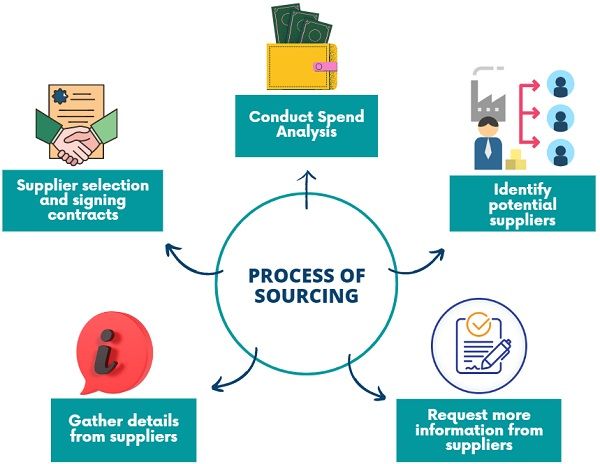

Process of Sourcing

Sourcing consists of numerous steps. These are:

- Carry out spend analysis of various types of products and services, which a manufacturing company requires.

- Depending upon the company’s requirements, suppliers are identified.

- After identifying the initial suppliers, the manufacturer requests more information from the supplier. For this, the buyer sends Request for Information (RFI), Request for Quotation (RFQ), and Request for Proposal (RFP) to the suppliers.

- The manufacturer sends them to the suppliers to gather details. This will help the manufacturer clarify who will be the right fit according to the needs and requirements. This process is called Supplier Qualification.

- Thereafter, the signing of contracts with the suppliers takes place. In this way, the suppliers turn out as vendors and the process of procurement starts.

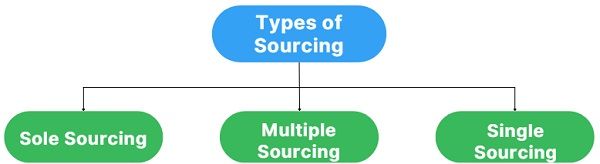

Types of Sourcing

- Sole Sourcing: It is when only one supplier of goods and services is available. This usually happens due to patents, technical specifications, raw materials, location etc.

- Multiple Sourcing: When the firm contracts with more than one supplier to provide goods and services, it is multiple sourcing. An example of multiple sourcing is that raw materials will be available at reasonable prices due to competition. Also, the flow of supply will remain uninterrupted. Moreover, it is the traditional approach to supply management,

- Single Sourcing: Systematic and objective decision of the firm to choose one supplier for supplying products and services when multiple sources are available is Single Sourcing. Automobile and component manufacturers follow a single-sourcing model in India. Further, single sourcing is a Japanese-suggested supply management approach. So, it is the modern approach. As per them, there are several benefits of Supply Management from a single source, that includes:

- Substantial reduction in inventory

- Reduction in planning and procurement costs

- Continuous cost reduction

- Faster new product introduction

Also Read: Difference Between Logistics and Supply Chain Management

What is Procurement?

Procurement means obtaining goods and services which the company requires to use as inputs for producing finished goods. By effectively managing the process of procurement of raw materials, the firm can manage the inventory-related cost in the best manner. For business corporations, procurement is a strategic function to control costs.

Do you know that the procurement process comprises a number of activities? The performance of these activities should take place sequentially, irrespective of the type of organization, ownership pattern, and material to be procured.

This function facilitates the uninterrupted flow of raw materials, parts and components for defined quality and quantity from suppliers to the production centre. These suppliers are quality certified. It involves:

- Ascertainment of the inputs which the firm needs both in terms of quality and quantity.

- Study of the sources of procurement

- Negotiating with suppliers and final supply contracts

- Order Placement

- Shipment of input consignment

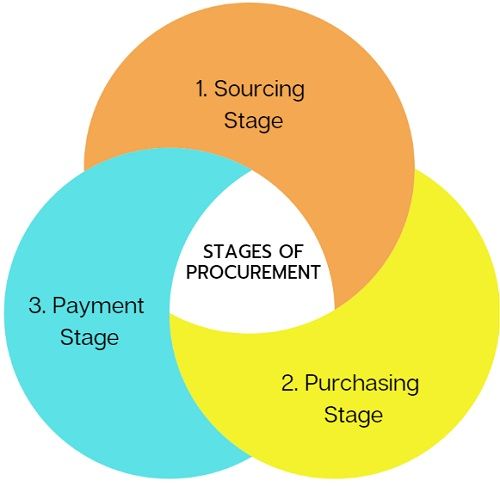

Stages of Procurement

- Sourcing Stage: It involves the primary steps wherein the company recognizes the needs for goods and services, creates purchase requests, evaluates suppliers and makes a selection, and builds strong business relationships with them.

- Purchasing Stage: It involves negotiating terms and conditions with the suppliers. Also, it encompasses the placement of orders and receiving and inspecting goods and services.

- Payment Stage: At this stage, the buyer approves the invoices, and the accounts department releases payment. Further, the careful maintenance of records of all the invoices, purchase orders and payment receipts takes place.

Also Read: Difference Between Purchasing and Procurement

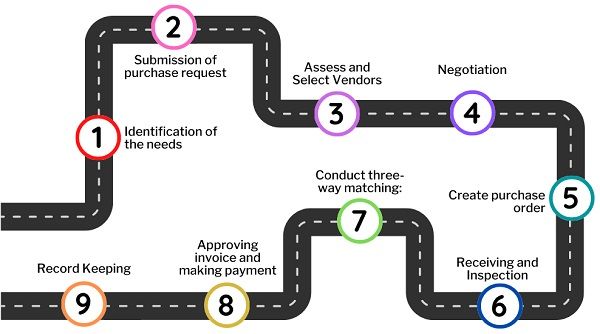

Process of Procurement

- Identification of the needs: The firm should figure out the needs for the specific product or service. The item could be a new or an existing one. It involves exploring the basic details of an enterprise’s needs like the exact technical specifications, material type, part number etc.

- Submission of purchase request: After the identification of business needs is over. The enterprise must procure the right quantity of supplies by sending a formal purchase request through a purchase requisition. Purchase requisition made by the concerned department, which requires material. It notifies the purchasing department that it needs to exist.

- Assess and Select Vendors: This step involves finding the best vendor and submitting an RFQ, i.e. request for quotation. The purchasing team sends RFQ to the potential suppliers to get the quote. It helps in making comparisons between various potential suppliers. At the time of assessment of vendors, apart from the cost, reputation, speed, quality, and reliability also plays a significant role.

- Negotiation: It is an ideal way to get a minimum of three quotes from the supplier’s end before making the final decision. For this, the company must examine each quote and negotiate the terms carefully.

- Create purchase order: Completing purchase order and sending the same to the supplier. It has to complete in all respects to identify the right set of materials and supplies. If only the purchase order is complete, the supplier will be able to meet the company’s requirements.

- Receiving and Inspection: Checking the items delivered to find out if there is any damage or if the quality is good or not. Thus, it ensures that the supplies are in the specified quantity. Also, it ensures that the quality of the material is as expected.

- Conduct three-way matching: Carrying out three-way matching. It is possible by tallying the purchase order, order receipt and invoice of goods. In case of any discrepancy, it is marked, and the issue is resolved before making the final payment.

- Approving invoice and making payment: When the three-way matching is accurate, the firm approves the invoices. After that, it makes payment to the supplier.

- Record Keeping: In this, the firm keeps a record of all the documents like invoices, receipts, order requisitions and other documents. These are important for taxation, auditing, restocking and various other purposes.

Also Read: Difference Between Purchase Requisition and Purchase Order

Key Differences Between Sourcing and Procurement

- Procurement refers to the process of managing a wide range of activities and processes related to the firm’s requirement for acquiring goods and services. These goods and services are needed by the firm to carry out production or to run the organization in an efficient manner. Conversely, Sourcing is the function of finding and then managing a source for input to carry out production.

- While sourcing is concerned with ‘who,’ i.e. the best supplier to provide the supplies. On the other hand, procurement is associated with ‘what’ supplies (kind and in how much quantity) the firm needs.

- Sourcing involves defining the need, market research, organizing source events, vetting suppliers and negotiating the contract. In contrast, procurement is the entire process that includes sourcing, sending purchase requisition, ordering, receiving and inspecting goods, making final payment and managing contracts.

- Sourcing is characterised by building and managing the supply chain and also creating a list of vendor options for resilience. However, procurement influences the supply chain to ensure that the flow of inputs and supplies is constant

- In sourcing, the firm identifies the suppliers to meet the needs of the business. As against, procurement is all about ensuring that the firm gets all that it needs for the smooth functioning of the business.

- Sourcing streamlines the procurement of materials, components and parts. At the same time, procurement ensures that there is a continuous flow of materials.

Conclusion

All in all, sourcing is a part of procurement, or we could say procurement includes sourcing. while sourcing involves selecting the best suppliers, procurement is obtaining the right kind and quantity of material at the right time and place.

Leave a Reply